Bar mill at Silat rolls all products

The new rebar and wire rod mill of Silat in the state of Ceara,Brazil, entered into production during March 2015. At present, all reinforcing bar sizes have been rolled successfully, ranging from 8-32 mm from a 130 x 130 mm x 12 meter billet.

All technological parameters for the mill were specified by Russula, while the mechanical equipment was designed and manufactured by Russula in Europe. Only the best materials and components were chosen, designed for high durability and long life. This equipment, combined with Russula’s advanced mill control, enables Silat to roll consistent, high quality product.

Fed by a 90 tph walking hearth reheating furnace, the plant layout includes a 20-stand continuous mill with two outlets, one for straight bar and the other for wire rod. The rod outlet includes a 10-stand, high-speed twist free finishing block fed from the bar mill finishing stands.

Pass Design

With the addition of the team in Massachusetts, Russula now has the ability to do complete pass design and commissioning. The full pass design for Silat was developed in house, with particular attention paid to the design of the slitting sequence. Multi strand slitting is complicated process that requires very precise control of the stock through the mill, and a pass design tailored to the customer’s specific requirements.

Generally speaking, most customers will want to produce rebar at a negative weight tolerance, normally ranging from -2% to -6%, depending on the specific country and location. If the pass design is not directly targeting the final desired weight, very often the mill will struggle to achieve consistency as the operators are continually working the mill to achieve a weight that they do not have a design for. In working directly with the customer, two set ups were produced for Silat, one at -4%, and a second at -2%.

By creating both of these settings, the mill has a structured approach on how to produce all sizes to both tolerances.

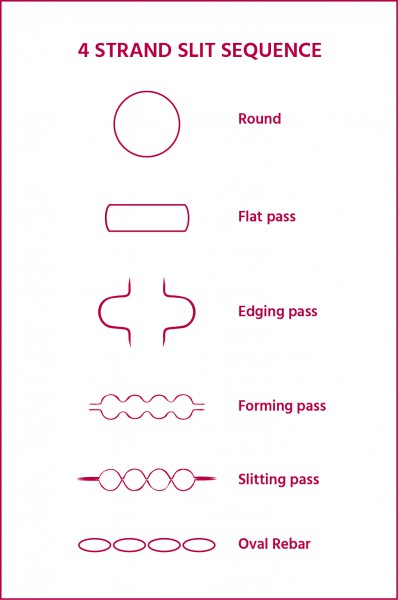

4 Slit Rolling

The smaller bar sizes, 8 and 10mm rebar, are produced by the four slitting to take advantage of the mill’s capacity for the entire product range. In June of 2015, the 4 slitting pass designs for 8 and 10 mm were successfully put into operation. With an outlet speed of 13 m/s for 4 x 8 mm, the mill produced high-quality 8 mm quenched and tempered rebar at a stable rate.

One of the challenges of slit rolling is the low life of the traditional slitting guide rolls. The reason is that in traditional slitting, the slit section is being pushed through the guide by the rolling mill stand. As such, the bar itself accelerates the slitter roll, leading to increased wear and higher cobble rates.

To address this common problem, Russula implemented a two stage powered slitter. Because the slitting rolls are turning with only a slight lead speed relative to the stock speed, life of the powered slitter rolls can be increased to values approaching 25,000 MT. Head end cobbles are naturally reduced because the head end of the slit section is not required to accelerate the rolls to the product speed. An additional challenge is to control precisely the entry of the stock throughout the entire slitting process, for this reason precision guiding is a requirement.