Noise and power reduction while operating at high speeds

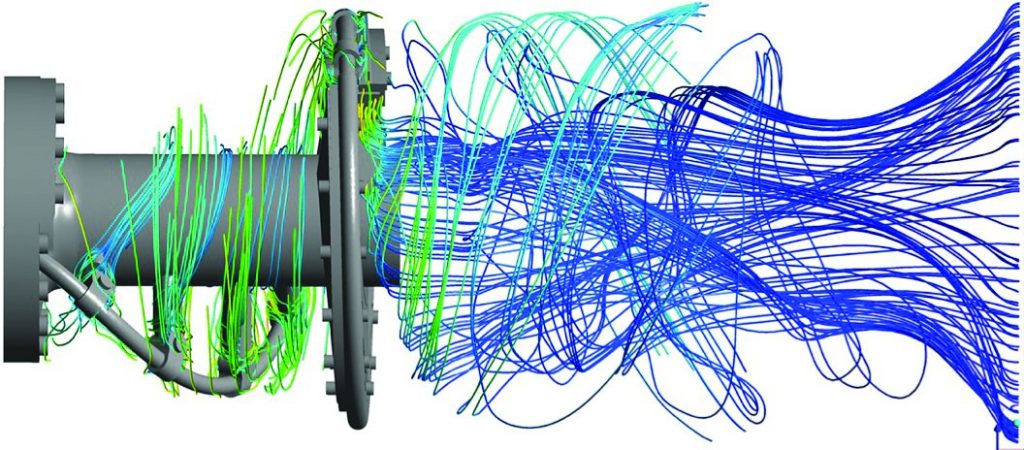

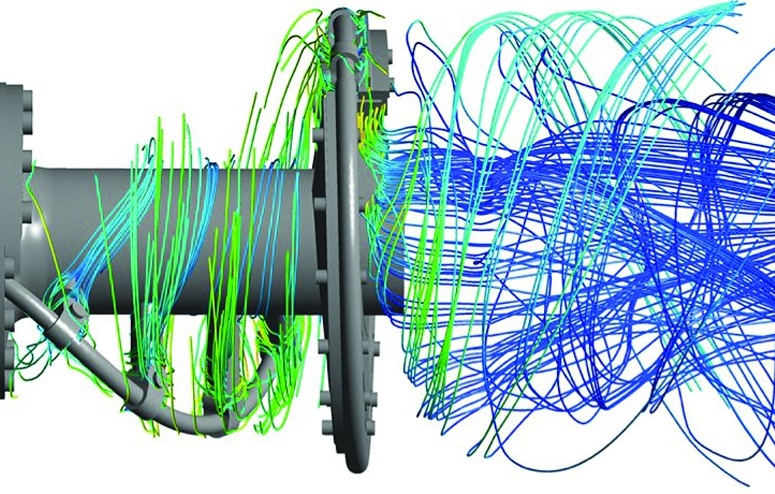

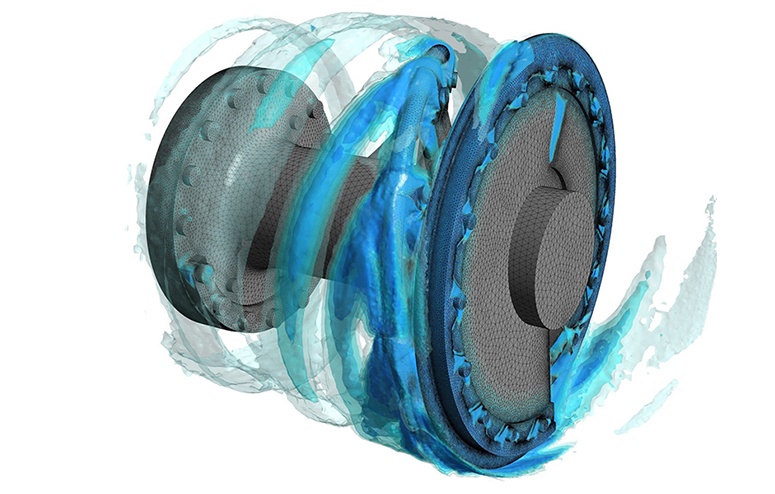

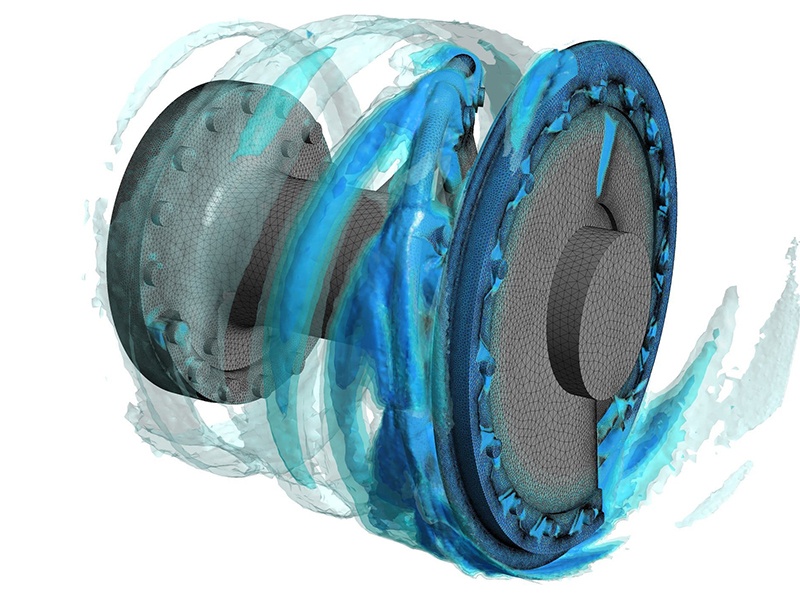

Russula performed a study on the laying head pipe support and frictional losses between the pipe support and the environment in which it operates. In conventional supports, under normal operating conditions, the scroll plate pushes air out of the way, which consumes a lot of power and generates a lot of noise. Like a typical rotary fan, one part of the total power consumed is directly proportional to the total pressure increase in the fan, and the air volume moved by the fan. In Russula’s laying head design, air is allowed to pass through pipe support airfoils so the air wraps around the supports and pipe, as shown in the top figure on the next page. In effect, this reduces the noise and power required to operate the laying head at high speeds.

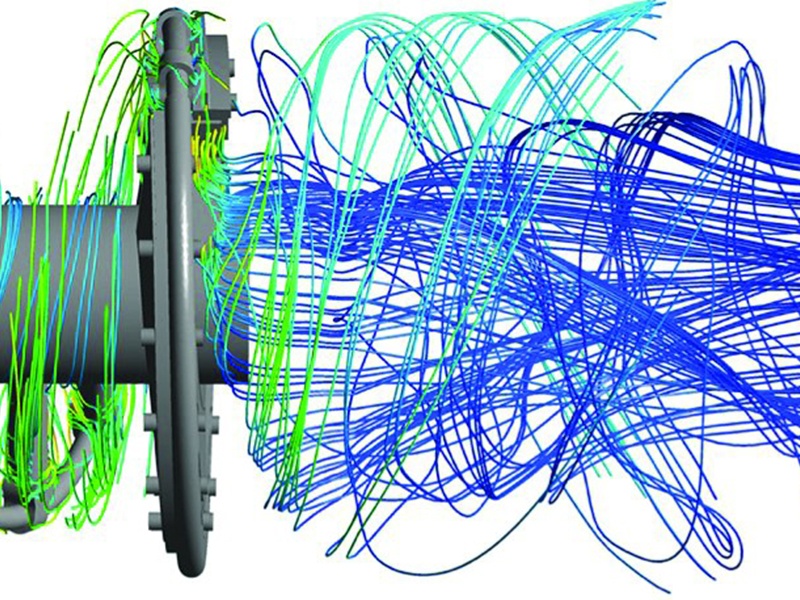

Because of the design of the airfoil supports, specifically the surface finish of the support and the overall tight balance, both the total pressure increase and the volumetric flow rate of air are reduced. The air flows around these supports instead of being pushed by them, as simulated in the bottom figure on the next page. This is a radical change from existing pipe supports currently available in the market. Reduction in aerodynamic load on the pipe support makes the operation of the laying head much more stable and controllable; the accuracy of front end positioning is improved.

The end result is that the audible signature of the machine is reduced, as well as the required power to run the equipment at both steady state and when fast, front-end positioning corrections are required. The noise reduction creates a friendlier work environment and the reduction in power consumption results in more energy savings for mills.