Now, this section mill is cobble-free when rolling UPN 30

New pass design finalized in 2 weeks using simulation software DEFORM®

One of Russula’s bar and section mill customers was having considerable difficulty in rolling UPN 30s without cobbling. Product defects and inconsistent performance were causing significant downtime. Even after readjusting the entire mill passes multiple times, there was still unstable rolling in every UPN 30 campaign. The final product was overfilled, leg length was longer than predicted and frequently out of tolerance.

Time was of the essence. The Russula Rolling Technology Center needed a simulation technology to identify and address design issues that were causing performance and quality issues on two different pass sequences for the same section. Russula reached out to the manufacturer of DEFORM®, Scientific Forming Technologies Corporation (SFTC).

DEFORM® is an engineering software simulator made to analyze complex material processes. It provides a virtual trial run environment that allows production testing on the computer, rather than on the rolling mill itself.

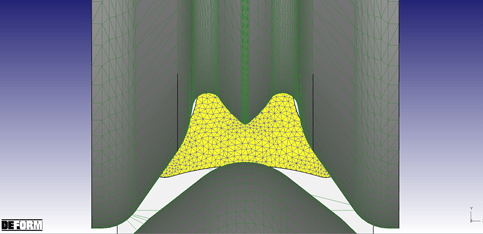

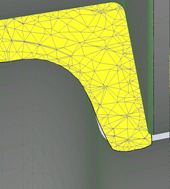

By using DEFORM®, the Russula and SFTC team revealed that the UPN 30 had voids on the 4th, 6th, 7th and 8th forming pass. Overfilling was also occurring on the 6th, 7th and 8th and final pass as well.

Simulation of the original design revealed there were voids on the 4th forming pass as featured here, as well as on the 6th, 7th and 8th pass

Voids and overfill on the 6th forming pass of the original design

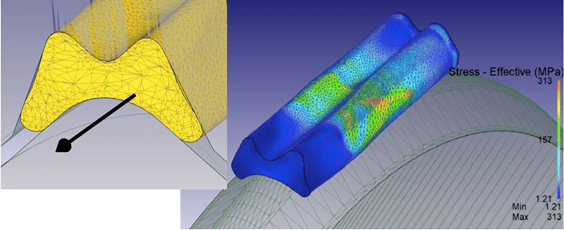

The UPN 30 2.5D and 3D simulations helped the team identify the problems and quickly propose workable solutions. The leg length was corrected and the overfill was eliminated. DEFORM® provided a fast, easy model set-up, and was able to capture transient behavior.

Leg length was corrected and overfill was eliminated by using the DEFORM simulation software

Using the DEFORM® software, reduced the amount of time that it would normally take to create a new pass design. The team was able to analyze, simulate and finalize a new design in two weeks. With the optimized pass sequence, the section mill was able to roll UPN 30 cobble-free with no overfill, no defects and within tolerance. It was clear from the start that the collaboration between Russula and SFTC could streamline the operations of many rolling mills in a short timeline.