Merchant bar and section mill in full operation at Dojran Steel

In January 2016, Dojran Steel, part of the Sidenor Group, the Steel Industry of Northern Greece, awarded Russula the contract to supply a new 350 kt/yr merchant bar and section mill. Driven by market demand, the first phase of the expansion project had to be completed in fifteen months.

On April 17, 2017 the Dojran and Russula team successfully completed the first phase and hot commissioned the new mill. Previously civil modifications to the existing building structure and foundation began in September 2016. The equipment installation began two months later.

Dojran Steel is located in Nikolic, FYROM, on the coast of the Dojran lake, almost 80 km from Thessaloniki, Greece. With the addition of the new merchant bar mill operations, Dojran Steel currently has a capacity of 200 kt/yr, which will increase in the subsequent phases of the project.

The modern merchant bar and section mill has enabled Dojran Steel to extend its market into rolling small and medium-sized merchant bars including:

Project Constraints

There were three major interrelated constraints during the course of this project; budget, space and time. In order to keep the project costs within the budget, a lot of the existing equipment was reused including the three-high roughing mill, universal stand cartridges, guides, cold shear, tying machines, quenching system and the water treatment plant. The electrical and mechanical revamp was divided into two phases. Phase I, which was commissioned in April, 2017 consisted in modernizing the intermediate and finishing mill, cooling bed and semi-automatic finishing end. Phase II will involves the installation of a new reheat furnace, roughing mill and automatic finishing end. Besides the cost savings advantage , a multiphase revamp approach reduces downtime and minimizes the impact on production.

Space became an important project constraint because the building was already erected, which housed the existing 50 kt/yr cross country mill that produced round bars and small sections. The new mill layout had to be designed accordingly to fit within the current space restrictions. Gearbox, spindles and motors were configured to avoid the building columns and foundations. Vertical stands were modified to fit into the height of the building.

Time was the most critical constraint in the project execution and mill commissioning. From receiving the order to the start-up, the entire project had to be completed in fifteen months. Since the existing cross country mill had to be shutdown in order to refurbish the equipment, install the new electrical and mechanical equipment and commission the new mill, the Sidenor Group redistributed the existing Dojran plant products among its other plants to remain competitive.

Project Layout

The overall scope of supply included engineering the rolling mill layout, roll pass design, new mechanical equipment, automation and on-site services such as supervision installation and commissioning.

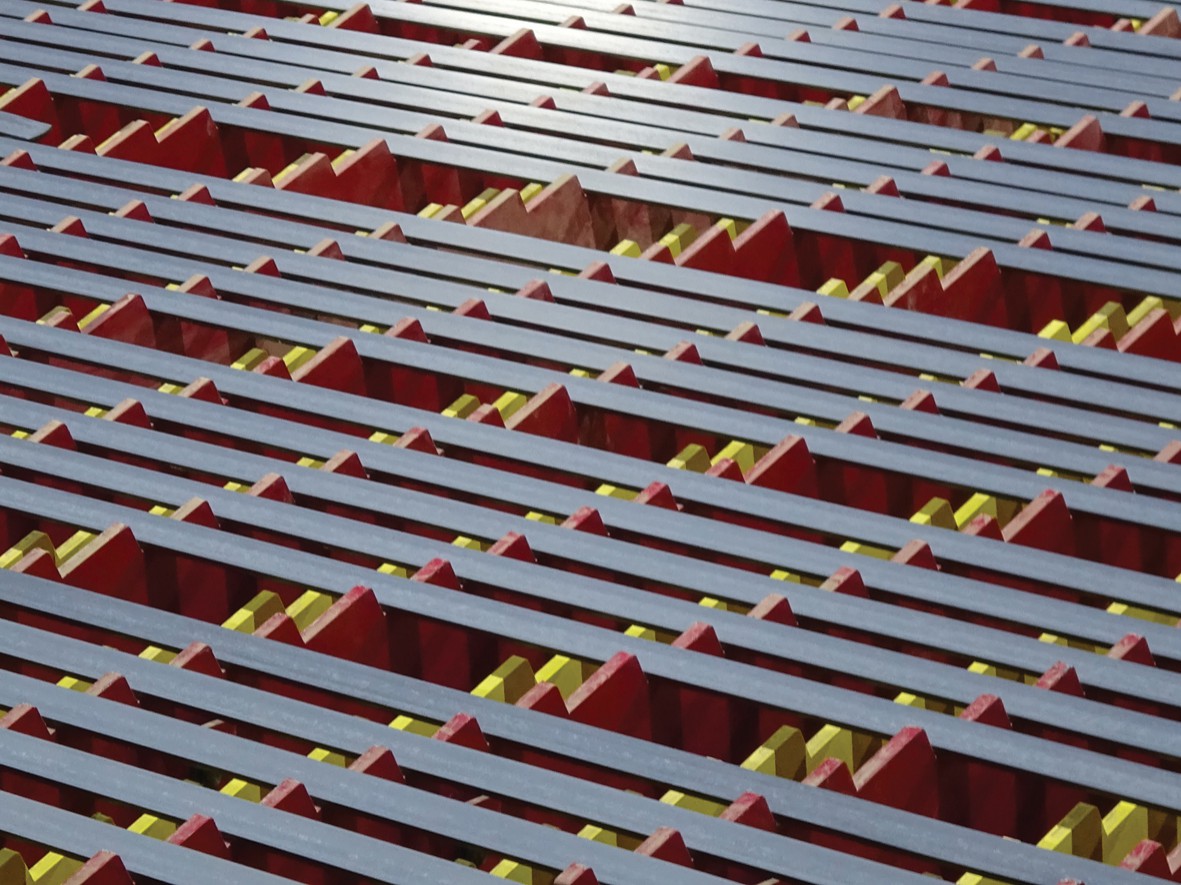

Russula designed the mill to roll bars and sections. The new rolling line at Dojran Steel has 18 new housingless stands in an H/V arrangement ranging in 3 different stand sizes. Seven vertical loopers, three start-stop shears, a dividing shear, bypass roller tables and conveying channels. The finishing area featured a rake type cooling bed. Russula supplied the complete mechanical and electrical equipment of the rolling line and the cooling zone as well as the bundling area.

Automation

The scope of supply included Levels 1 process automation, using Siemens' Tia Portal and ABB drive platform, HMI and IBA data acquisition system.

The new mill control at Dojran Steel consits of a cascade system based on the R-factor simplifies the setup and operator control. Tension and loop control along the mill reduces dimensional defects. Advanced tracking systems and shear cut control optimize the bar length using all available shears in the mill. Laser speed measurement instrumentation ensure high precision and reliable measurement. The automation was implemented to easily incorporate the Phase II expansion project in the future.

Results

In a joint collaboration between Dojran Steel and Russula, the mill started up as scheduled fifteen months after the contract award date. The outcome of the expansion project was a resounding success. There were no major delays during the project execution and startup of operations.

With the new merchant bar and section mill, Sidenor has expanded its production capacities for structural steels. The new plant is designed to produce a wide range of end products, including small and medium-sized merchant bars, flats, small equal angles, square bars, UPN channels, IPE and T sections.