Phase 1: Stacker Upgrade at Nucor Utah

Over the course of four years, Nucor Steel Utah and Russula upgraded the automation and drives of rolling mill #2. The project was broken down into three phases. For all phases of the project Russula supplied the electrical and controls solution, installation supervision, commissioning and training.

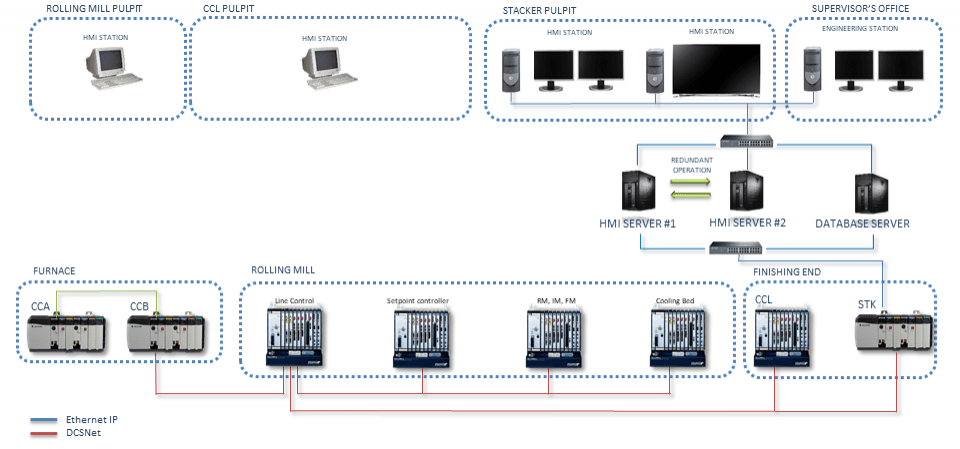

The first phase encompassed the upgrade of the rolling mill #2 stacker, evacuation area and storage tables. Russula supplied new Rockwell Powerflex 755 AC drives and new ABB DCS800 DC drives for the magnet power supplies. A selection of hardware was chosen specifically for this project, including Rockwell ControlLogix PLCs, Rockwell GuardLogix PLCs, and FactoryTalk HMI. GuardLogix, a safety PLC, was deployed in 4 defined safety zones with locking gates equipped with ´request to enter´ and ´reset´ buttons. All communication between the PLCs, drives, new operator desks and remote I/O stations are transmitted over Ethernet IP. The new control system improved the safety of the stacker for the operators and maintenance staff.