Gerdau Charqueadas Phase 3 electrical upgrade

After the successful commissioning of Phases 1 and 2 of the automation and electrical upgrade at the SBQ combined bar and wire mill in Charqueadas, Brazil, the Gerdau and Russula team successfully put into operation Phase 3 on September 6, 2023.

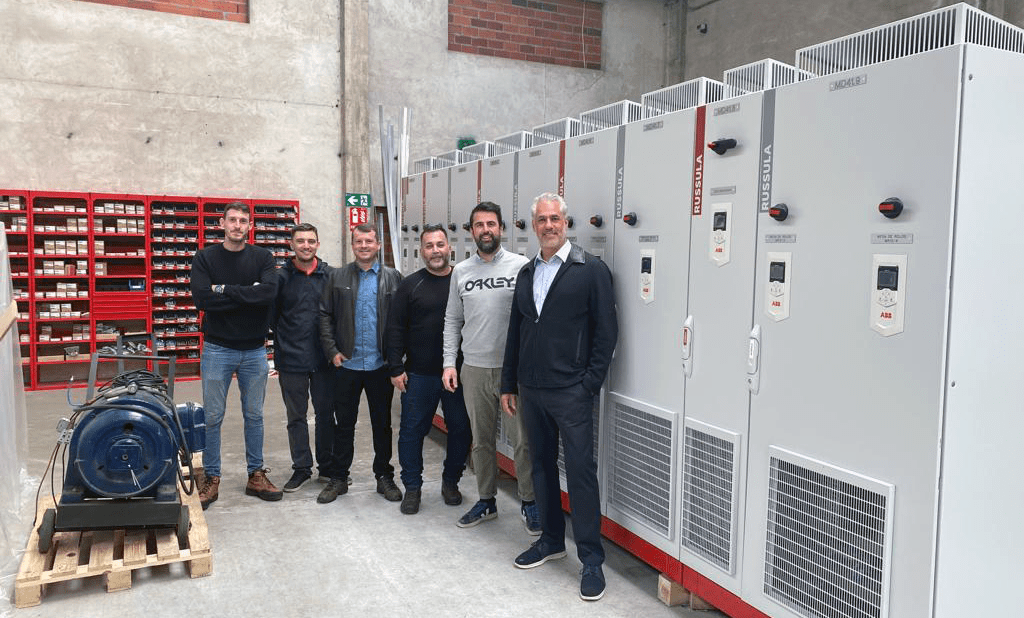

Phase 3 commissioning of rolling mill #2 electrical upgrade at Gerdau Charqueadas in September 2023

Automation and drives upgrade for rolling mill #2 with three outlets: bars, wire rod and Garret coiler

Divided into three phases, the electrical and automation upgrade was for the entire rolling mill #2, from the reheat furnace to the three outlets: bar, wire rod and garret coiler. The project took place over a period of three years. Phase 3 consisted of replacing the remote IOs and supplying new AC multidrives for the roller tables, pinch rolls, kocks car and shear #4.

Phase 1:

- Startup: March 2020

- Scope: Automation and DC drives upgrade for bar mill and bar outlet

Phase 2:

- Startup: December 2021

- Scope: Automation and DC drives upgrade for wire rod outlet and garret coiler

Phase 3:

- Startup: September 2023

- Scope: Remote IOs for the rolling mill #2 and AC multidrives

Every phase of this project has been successful due to our outstanding relationship with the Gerdau Charqueadas team. It has been a pleasure to work with them and perform a complete modernization of the mill’s automation and electrical systems.

Bruno Sabença - Russula’s Automation/PLC/Customer Service Engineer in South America

Scope of Supply

All remote IO ET200U units’ hardware corresponding cabinets and operator panels were replaced with new cabinets and operator panels prewired with the new S7 hardware compatible with the S7-1500 hardware that was included in the main project. New multidrives replaced the existing Siemens Simovert Masterdrives. This new equipment was supplied mounted in new cabinets and designed to match the incoming cable leads and motors. As part of the services scope, Russula provided spare parts, electrical installation supervision and commissioning support.

Factory Acceptance Test at Russula Headquarters and Workshop

Earlier in 2023, the Gerdau team returned to A Coruña to witness the Factory Acceptance Test (FAT) at the Russula workshop and headquarters.

Gerdau Charqueadas team visits Russula headquarters and workshop for the Factory Acceptance Test

Successful commissioning in September 2023

During a shutdown in September 2023, phase three of the rolling mill #2 electrical and automation upgrade was completed. More than 40 local panels were installed with Siemens ET200 SP remotes, and ABB ACS 880 multidrive and a distribution center. All the new electrical equipment communicates to three Siemens S7 1500 CPUs via Profinet.